Discover Javelin's 3D Technology at the Global Petroleum Show in Calgary

3D Printing Applications in Oil and Gas Industry Aurum3D

Posted October 19, 2021. Advancing the use of 3D printing in natural gas and oil operations - a technology that can significantly reduce lead times and drive efficiency, safety and other technological improvements across all oil and gas segments - is the focus of API's newest standard released this week. The first edition of Standard 20S.

BP Studies the Impact of 3D Printing on the Oil Industry All3DP

3D printed parts could benefit oil & gas, offshore and maritime supply chains. Trust is key to unlocking additive manufacturing's potential for your business. We look at the top benefits of, and barriers to, this technology, and how DNV can help your sector to use it to become safer, more efficient and more sustainable.

API's new 3D printing standard to help “strengthen the supply chain resiliency” of oil and gas

Conclusions. 3D printing technologies have already started transforming the oil and gas industry. Oil and gas companies have been investing in 3D printing machines and materials to boost operational efficiency, control operational costs, speed up production, and simplify complex supply chains. Also, many manufacturers have started developing.

Oil and Gas 3D Animation Drilling Rig YouTube

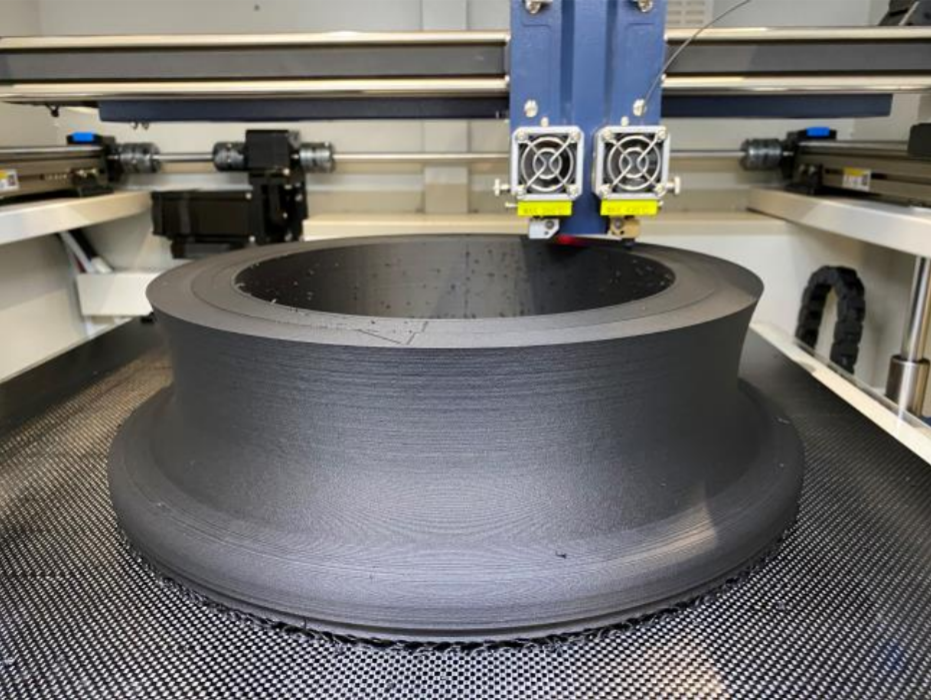

Sand Printing Systems Skip Tooling and Assembly. ExOne's family of sand 3D printers is the most popular in the world for digital manufacturing of sand cores and molds for metalcasting. With our trusted machines, you can go from design to metalcasting in hours or days instead of weeks and months. No more patterns needed for sand molds.

New Collaboration to Support Advances in 3D Printing Oil & Gas News

3D printing brings certain advantages to the oil & gas industry. These benefits will drive the future of the industry. Reduced costs. With constant pressure to reduce oil prices, oil & gas companies are influencing component manufacturers to reduce their manufacturing costs and shorten the lead times. With this backdrop, manufacturers are.

GE Oil & Gas Adds 3D Printing Line at Talamona Plant

According to recent reports, 3D Printing in the oil and gas sector is expected to be worth $32 billion by 2025. Although 3D Printing accounts for just 0.1% of the global manufacturing market at present, increased adoption of the technology suggests that it could be worth as much as $60 billion by 2030.

3D Printing in the Energy, Oil and Gas Industry Airport Boulevard B, 77836 Rheinmünster

3D printing in the oil and gas sector is an area of increasing development in recent years. Although far from widespread adoption, much work is being done to spread awareness of the possibilities.

3D Printing in the Oil and Gas Industry IC3D Printers

New centre will foster trust in 3D printing for oil and gas industry. There is currently no standardized way of proving to manufacturers and regulators that 3D-printed products are safe to use. "Part-by-part certification is costly, time-consuming, and counter to producing and using additive manufacturing parts on demand," said Kandukuri.

3D Printing and What It Means for the Oil Industry

British multinational oil and gas company BP has confirmed it is using 3D printing to manufacture components for its petrochemicals business. The company previously began integrating additive.

How 3D Printing Will Transform the Oil and Gas Industry

Paul Hanaphy September 16th 2021 - 11:58am 0 0. Around 83% of oil and gas companies are considering adopting 3D printing or on-demand manufacturing to meet their spare part production needs.

Is the Oil & Gas Industry Ready for 3D Printing? AMFG

3D printing has tremendous potential in the oil and gas industry in delivering productivity gains, according to GlobalData. It is expected to gain further market penetration and find new use cases with greater collaboration between industry and technology players in developing more purpose-built 3D printing materials and solutions.. Here are the key technology trends impacting the 3D printing.

3D Printing Brings New Opportunities and New Challenges to the Oil & Gas Industry

3D Printing Set to Transform Oil & Gas Industry. by Ile Kauppila. Published Dec 2, 2021. Oil & gas producers are turning to 3D printing to solve supply chain problems and innovate faster. Let's look at how 3D printed parts boost productivity and cut costs from the oilfield to the refinery. Advertisement.

3D expands fleet of polymer 3D printers for highend defense, maritime and oil and

3D printing benefits and applications in the oil and gas industry. 1. Faster product development and design flexibility. One of the key benefits of 3D printing is its ability to speed up the product development process. Using additive manufacturing, product designers and engineers can visualise, develop and validate their designs quickly and.

Industrial Oil Refinery 3D Model by virtual3d

The oil and gas industry requires parts to meet robust performance and environmental standards. Newly developed 3D printing materials like Antero 800NA, a PEKK-based thermoplastic, combine hydrocarbon resistance, good tensile properties, and high heat-deflection. One increasingly crucial application of 3D printing in the energy sector is seen.

Oil Industry to Look Into 3D Printing Dashboard

Today, 3D printing is used in every industry to produce everything from prototypes, tools and jigs to components and end-use parts.. many countries will continue to consume energy produced by burning fossil fuels like oil, natural gas and coal. 3D printing holds the key to accelerating the adoption of renewable energy and helping to make.

Oil & Gas Plant 3D Animation Modeled in Aveva Pdms (SKH) YouTube

3D Printing for Semiconductors: Market Opportunity Brief. April 22, 2024. Report # AMR-3DPSEMI-0424

.